Dezhou Guanlu Precision Machinery Co.,Ltd

Statement:

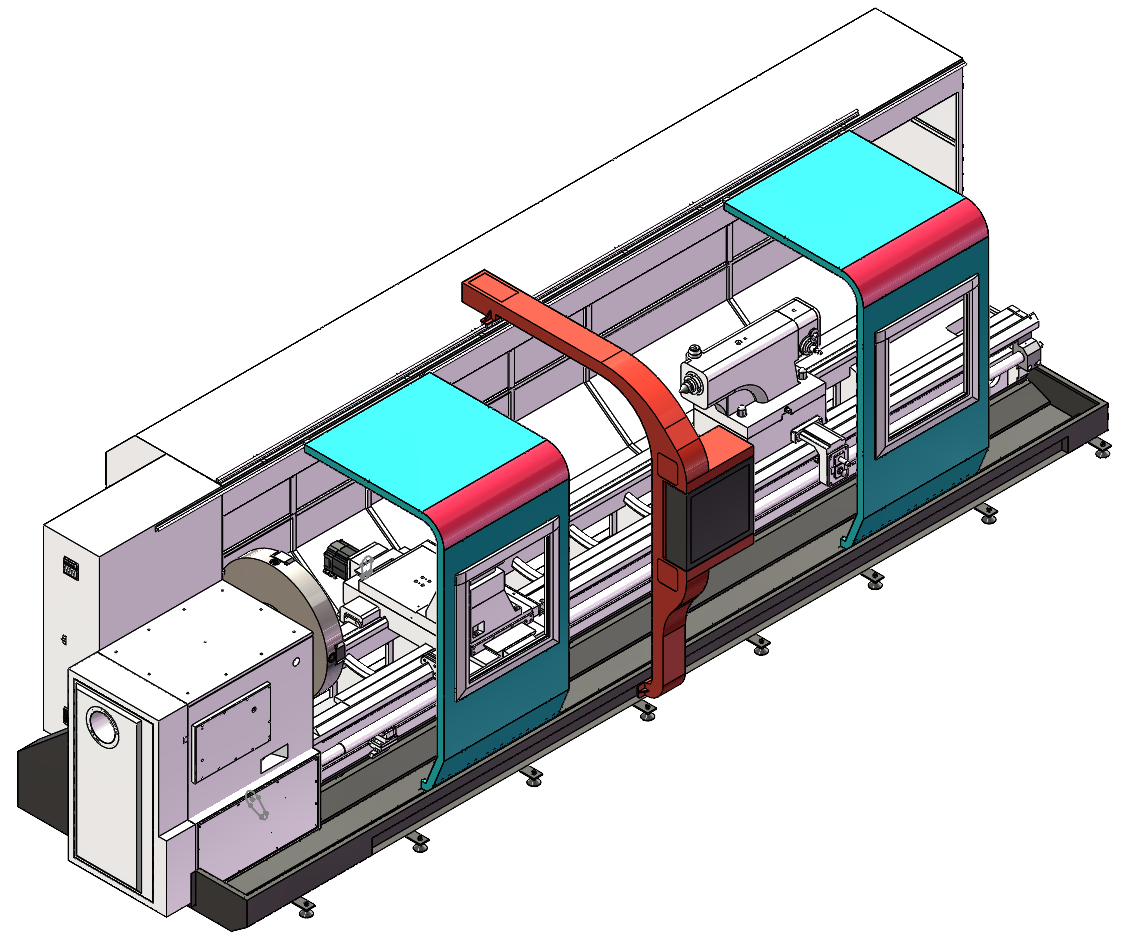

CNC horizontal large lathe is manufactured by Shandong Tongyuan Heavy Industry company,which is sister company of Dezhou Guanlu Precision Machinery company.

We manufacture the following CNC horizontal large lathes models:

CK611-L,CK611-M,CK611-H

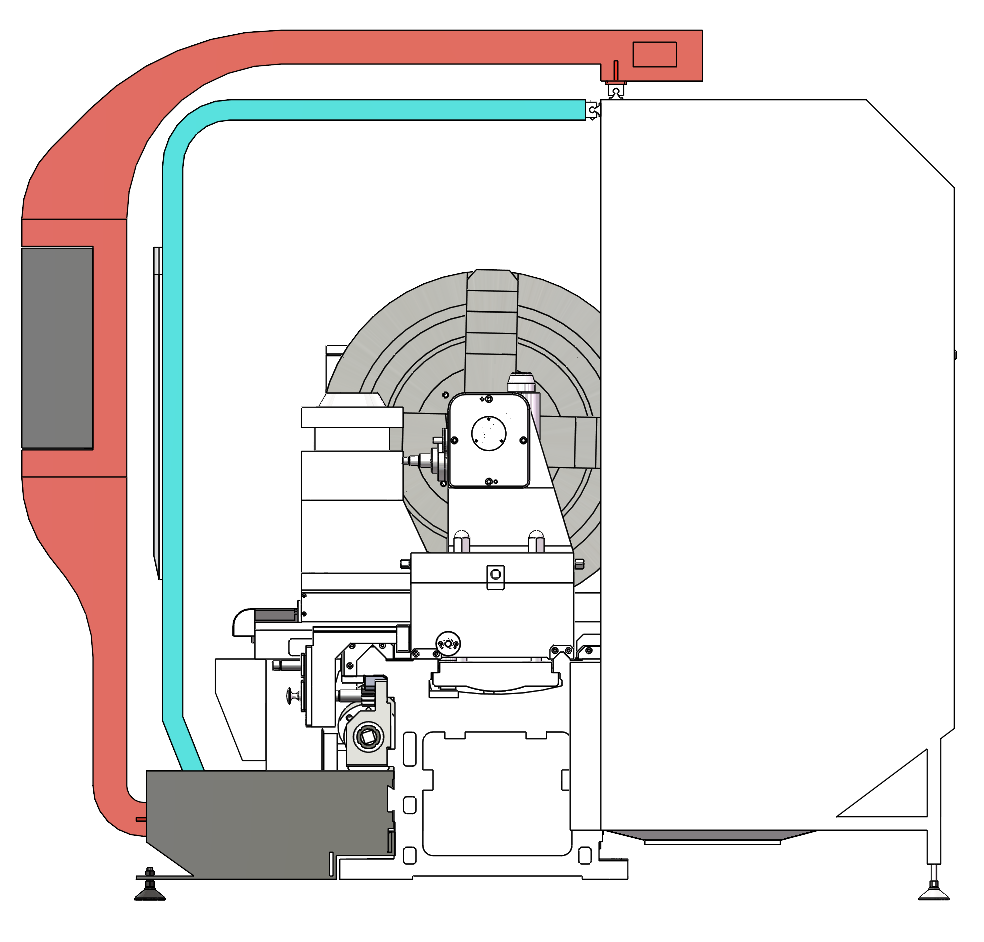

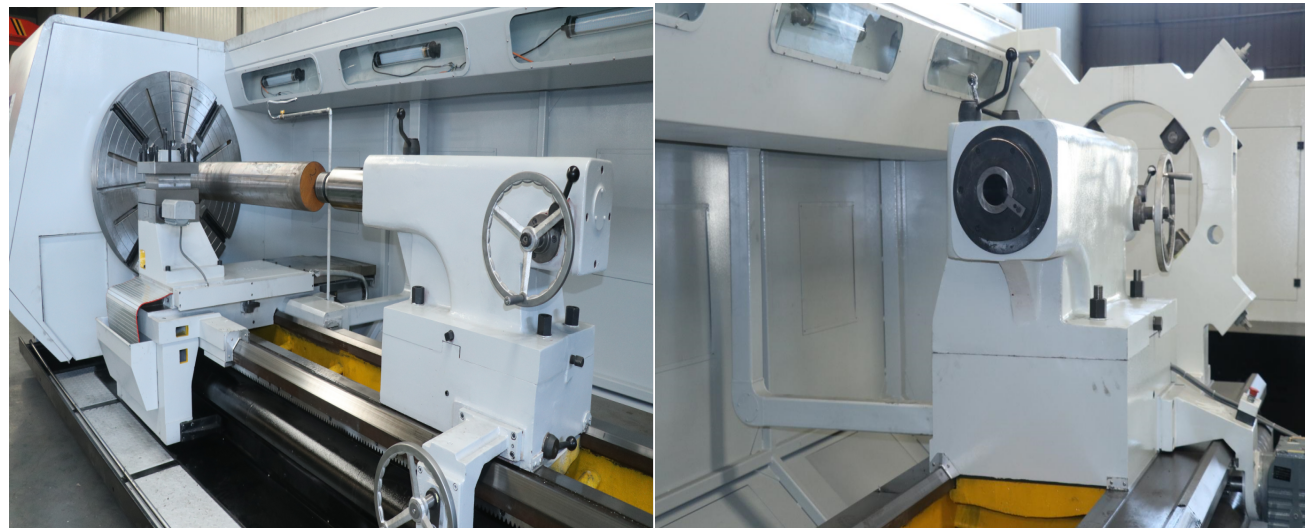

The above CNC large lathes has large horizontal flat bed, adopt SIEMENS or FANUC CNC system, and full digital AC servo system. The main drive for turning is automatic four-speed stepless speed change, the main motor is an AC spindle motor, two linkage control axes are used. For center distance of Z-axis and X-axis between 1-5M, we adopt ball screw pair and AC servo motor to realize longitudinal and lateral movement; If the center distance is more than 6meters, Z-axis adopts a rack and pinion transmission and a grating ruler, while the X-axis adopts a ball screw pair plus AC servo motor to achieve longitudinal and lateral movement, with good positioning and repeat positioning accuracy.

The main components and structure of the machines are optimized designed, the stability of the whole machine is excellent. Applicable to energy, chemical industry, light industry, electromechanical, paper-making, automobile industry and other industries. It has the characteristics of high precision, high power, high rigidity and high automation. It is suitable for processing shaft, sleeve and disc parts. Such as turning inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end surfaces, grooving, chamfering, threading, etc., the process has strong adaptability, high processing efficiency, simple operation, and comprehensive functions, which can reduce the need for skilled workers. requirements, it is an ideal machining equipment.

The CNC horizontal lathe machine could have the function of milling,grinding,drilling,boring. If need,please notice.

Machining facilities:

We have strong machining facility to produce the big lathe machines:

12meters Germany Heckert gantry type guide rail grinder(machining accuracy is 2-3um/1000mm),Japanese brand NSK five face milling machine,JIER 12meters gantry type planner,Coordinate boring machine,Vertical milling centere,CNC lathe,plan milling machine,quench machine,vertical milling machine,CNC lathes,Radial drilling and so on.

Technician teams:

CNC large lathes,we have four technicians to design the drawings,all of them are has more than 10years working experience.They resigned from famous chinese large lathe manufactures and joined to us.

Skilled assemble workers:

More than 10 skilled assmeble team,averagely has more than 5 years assemble experience. Machined by good machining facilites,designed by talent technicians,assembled by skilled engineers,our CNC large lathe machines are all in stable performance and extremly accuracy.

Certificates: we have past the ISO9001 quality management system certificate,CE quality management system certificate,Enviroments management system certificate,occupation monitoring management system certificate and so on.

Packing: All machines could be loaded into 40feet GP. Packed by wooden pallets and fasten into the containers.

Machine bed width and guide quantity: Difference models has different machine bed width and swing diameter. According to the loading capacity,we will recommend different guides,we have two guide rails bed,three guide rails and four split guide rails.

Please read the following details of our models to choose your right machine or just send email to tell us your requirements:

CK61xx L series with different models:

Loading capacity:6tons

Machine bed:755mm width

Item | Machine model | |||||||

CK61100L | CK61125L | CK61140L | ||||||

CNC Turning and boring function | Optional; After adding this functional part, deep hole boring machine processing and deep hole turning processing can be realized. | |||||||

CNC Turning and milling function | Optional; After adding this functional part, drilling and simple milling can be realized. | |||||||

CNC Turning and grinding function | Optional; After adding this functional part, the abrasive belt grinding of the outer circle can be realized. | |||||||

Chuck | Standard | Φ1000mm | ||||||

Special ordered Parts | Φ1250 Φ1400mm | |||||||

Center Frame | Standard | Φ70-480mm | ||||||

Special ordered Parts | Φ400-700mm | |||||||

Turret | Standard | LDB4-157 | ||||||

Special ordered Parts | Optional according to user requirements | |||||||

Roller | Standard | No, special order is available | ||||||

Item | Machine model | |||||||

CK61100L | CK61125L | CK61140L | ||||||

Max. loading capacity of two centers | 6000kg | |||||||

Machine bed width | 755mm | |||||||

Max.swing diameter over bed | 1040mm | 1290mm | 1440mm | |||||

Max.swing diameter over turret | 630mm | 880mm | 1030mm | |||||

Max.workpiece Length | 1000-16000mm(More than 6m is driven by rack and pinion) | |||||||

Headstock Parameters | ||||||||

Spindle front bearing diameter | 200mm | |||||||

Spindle bore diameter | Φ130mm | |||||||

Spindle taper | Metric 140# | |||||||

Spindle speed series | Hydraulic four gear, stepless speed regulation within gear | |||||||

Spindle rotary speed range | 5-500r/Min | |||||||

Main motor power | 37kW | |||||||

Infeed system parameters | ||||||||

SIEMENS CNC control system | ||||||||

Longitudinal servo motor torque | 30N.M | |||||||

Transverse servo motor torque | 28N.M | |||||||

FANUC CNC system | ||||||||

Longitudinal servo motor torque | 30N.M | |||||||

Transverse servo motor torque | 22N.M | |||||||

Cutter bar cross section | 40×40 | |||||||

Turret workstation quantity | Vertical type 4 station | |||||||

Cutter disc Repeated positioning accuracy | 0.01mm | |||||||

Longitudinal Rapid feed rate | 4000mm/Min | |||||||

Transverse Rapid feed rate | 4000mm/Min | |||||||

Longitudinal feed speed | 1-2000mm/Min | |||||||

Transverse Infeed speed | 1-2000mm/Min | |||||||

Tailstock parameters | ||||||||

Tailstock sleeve diameter | 160mm | |||||||

Tailstock sleeve taper | Morse 6# | |||||||

Tailstock sleeve stroke | 300mm | |||||||

CK61xx M series with different models:

Loading capacity:10tons

Machine bed:1100mm width

Part name | Machine model | ||||

CK61125M | CK61140M | CK61160M | CK61180M | CK61200M | |

Maximum load-bearing capacity of the two center | 10000kg | ||||

The width of machine bed | 1100mm | ||||

Max. Turning diameter over the machine bed | 1290mm | 1440mm | 1640mm | 1840mm | 2040mm |

Max. Turning diameter over the tool holder | 900mm | 1050mm | 1250mm | 1450mm | 1650mm |

Max. Length of the job | 1000-16000mm | ||||

Parameter of spindle box | |||||

Spindle front bearing diameter | 200mm | ||||

Diameter of spindle through hole | 130mm | ||||

Spindle taper hole | Metric 140# | ||||

Spindle speed series | Hydraulic 4 gear, stepless speed regulation in gear | ||||

Spindle speed range | 5-500r/Min | ||||

Main motor power | 37kW | ||||

Parameter of feeding system | |||||

SIEMENS CNC controller | |||||

Longitudinal servo motor torque | 30N.M | ||||

Transverse servo motor torque | 28N.M | ||||

FANUC CNC controller | |||||

Longitudinal servo motor torque | 30N.M | ||||

Transverse servo motor torque | 22N.M | ||||

Tool bar cross section | 40×40 | ||||

Number of tool holder stations | Vertical 4 station | ||||

Repeated positioning accuracy of tool chuck | 0.01mm | ||||

Longitudinal fast forward speed | 4000mm/Min | ||||

Transverse fast forward speed | 4000mm/Min | ||||

Longitudinal feed rate | 1-2000mm/Min | ||||

Transverse feed rate cutter plate | 1-2000mm/Min | ||||

Parameter of tailstock | |||||

Tailstock sleeve diameter(spindle turning) | 260mm | ||||

Tailstock taper hole | Metric 80# | ||||

Tailstock sleeve stroke | 300mm | ||||

CK61xx H series with different models:

Loading capacity:16tons

Machine bed:1100mm width

Item | Model | ||||

CK61125H | CK61140H | CK61160H | CK61180H | CK61200H | |

Max. loading capacity of two centers | 16000kg | ||||

Machine bed width | 1100mm | ||||

Max.swing diameter over bed | 1290mm | 1440mm | 1640mm | ||

Max.swing diameter over turret | 900mm | 1050mm | 1250mm | ||

Max.workpiece Length | 1000-16000mm | ||||

Headstock Parameters | |||||

Spindle front bearing diameter | 240mm | ||||

Spindle bore Hole Dia | 130mm | ||||

Spindle taper | Metric 140# | ||||

Spindle speed series | Hydraulic four gear, stepless speed regulation in gear | ||||

Spindle rotary speed range | 5-500r/Min | ||||

Main motor power | 45kW | ||||

Infeed system parameters | |||||

SIEMENS CNC control system | |||||

Longitudinal servo motor torque | 30N.M | ||||

Transverse servo motor torque | 28N.M | ||||

FANUC CNC system | |||||

Longitudinal servo motor torque | 30N.M | ||||

Transverse servo motor torque | 22N.M | ||||

Cutter bar cross section | 40×40 | ||||

Turret workstation quantity | Vertical type 4 station | ||||

Cutter disc Repeated positioning accuracy | 0.01mm | ||||

Longitudinal Rapid feed rate | 4000mm/Min | ||||

Transverse Rapid feed rate | 4000mm/Min | ||||

Longitudinal feed speed | 1-2000mm/Min | ||||

Transverse Infeed speed | 1-2000mm/Min | ||||

Tailstock parameters | |||||

Tailstock sleeve diameter | 260mm | ||||

Tailstock sleeve taper | Metric 80# | ||||

Tailstock sleeve stroke | 300mm | ||||

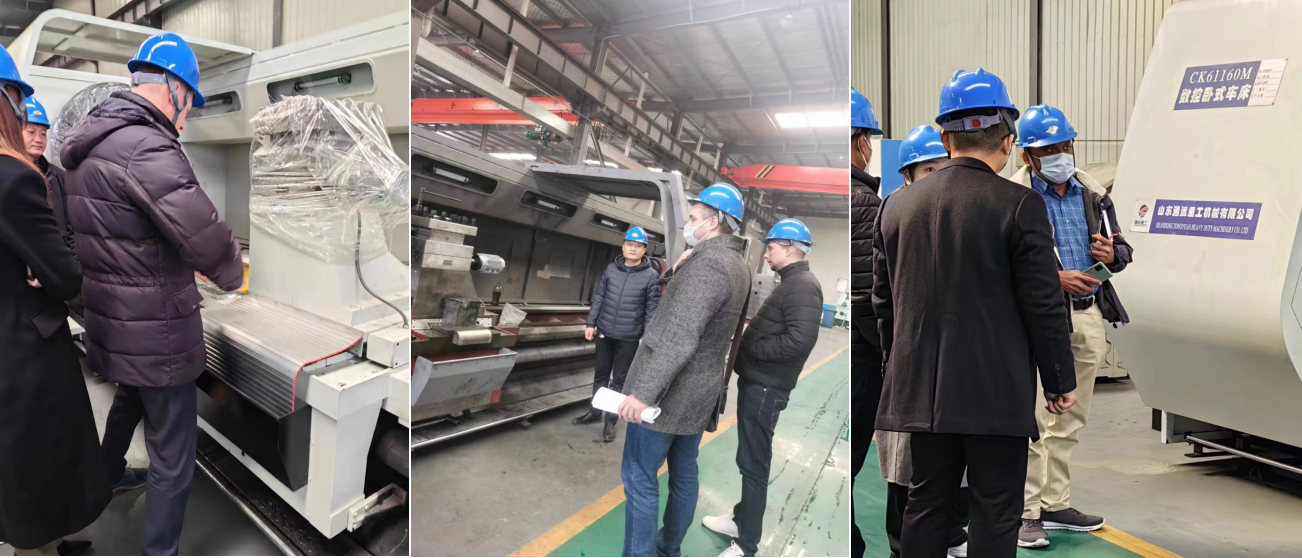

Customer visiting:

Please contact me directly: susan@tongyuanlathe.com

Mobile/wechat/whatsapp:+8615165964868