Dezhou Guanlu Precision Machinery Co.,Ltd

contact us

contact us

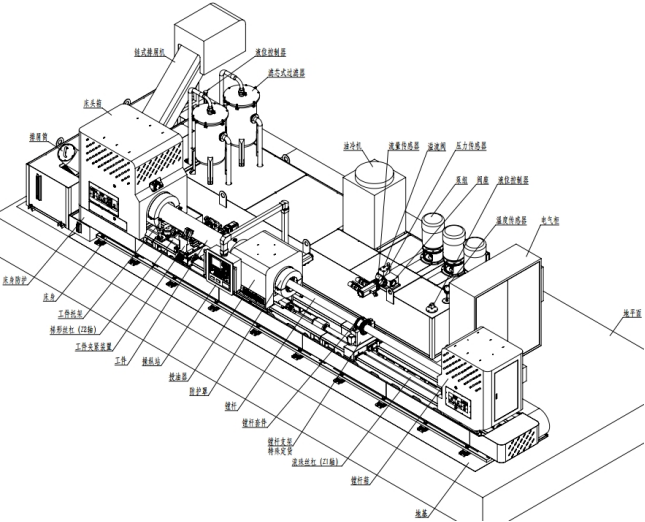

It is a machine tool specially designed for compound machining. The machine tool is suitable for processing various hydraulic cylinders, spindle holes, cylinder holes and cooling holes. The hole size accuracy of the processed parts can reach IT7 ~ IT9, and the surface roughness of the inner hole after rolling: Ra0.05 ~ 0.4 μm.

All the castings of the machine tool adopt the design concept of box structure, and are optimized by finite element analysis, so that they have the characteristics of reasonable quality, high rigidity and high precision.

Items | Primary parameters | remark | ||

|

|

| ||

|

| |||

|

| |||

|

| |||

机床性能 |

(Boring Box Feed) |

|

| |

|

| |||

|

| |||

(Oil Dispenser Movement) |

|

| ||

|

| |||

|

|

| ||

|

| |||

|

|

|

| |

|

| |||

| 转速范围 |

|

| |

|

| |||

|

|

| ||

|

| |||

|

|

|

| |

|

|

| ||

| 16bar | |||

|

|

| ||

| 50μm | |||

|

| |||

|

|

| ||