Dezhou Guanlu Precision Machinery Co.,Ltd

please visit our Youtube

Dezhou Guanlu Precision Machinery Co.,Ltd

Statements: CNC vertical lathe is not manufactured by Dezhou Guanlu,but it is partner products.

The company is specializing in the production of various CNC single and double column vertical lathes Since 2007, So far, the company has a total of 6 series and more than 30 kinds of vertical lathe products, which can provide alternative imported vertical lathes for aerospace, national defense and military industry, energy, rail transit, shipbuilding, engineering machinery and other industries, and it has initially possessed the foundation and conditions for competition with international advanced products.

CK51E CNC Vertical lathe series(Four models available,email to get more details)

Product structure features:

1.This series of new CNC single-column vertical lathe is our company that has absorbed the advanced design and manufacturing technology of the contemporary era, adopted the CAD optimization design method, adopted the latest design concept, implemented the current national accuracy standards and our factory's stiffness standards, equipped with advanced functional parts at home and abroad, and achieved strong cutting in terms of structural performance. The worktable is overloaded, the machine tool has high dynamic and static stiffness, and each top movement is safe and reliable, High-tech mechatronic products with long service life and high processing efficiency.

It is applicable to cemented carbide and ceramic tools, and can rough and finish the inner and outer cylindrical surfaces, inner and outer conical surfaces, plane and circular surfaces of parts made of ferrous metals, non-ferrous metals and some non-metallic materials at high speed.

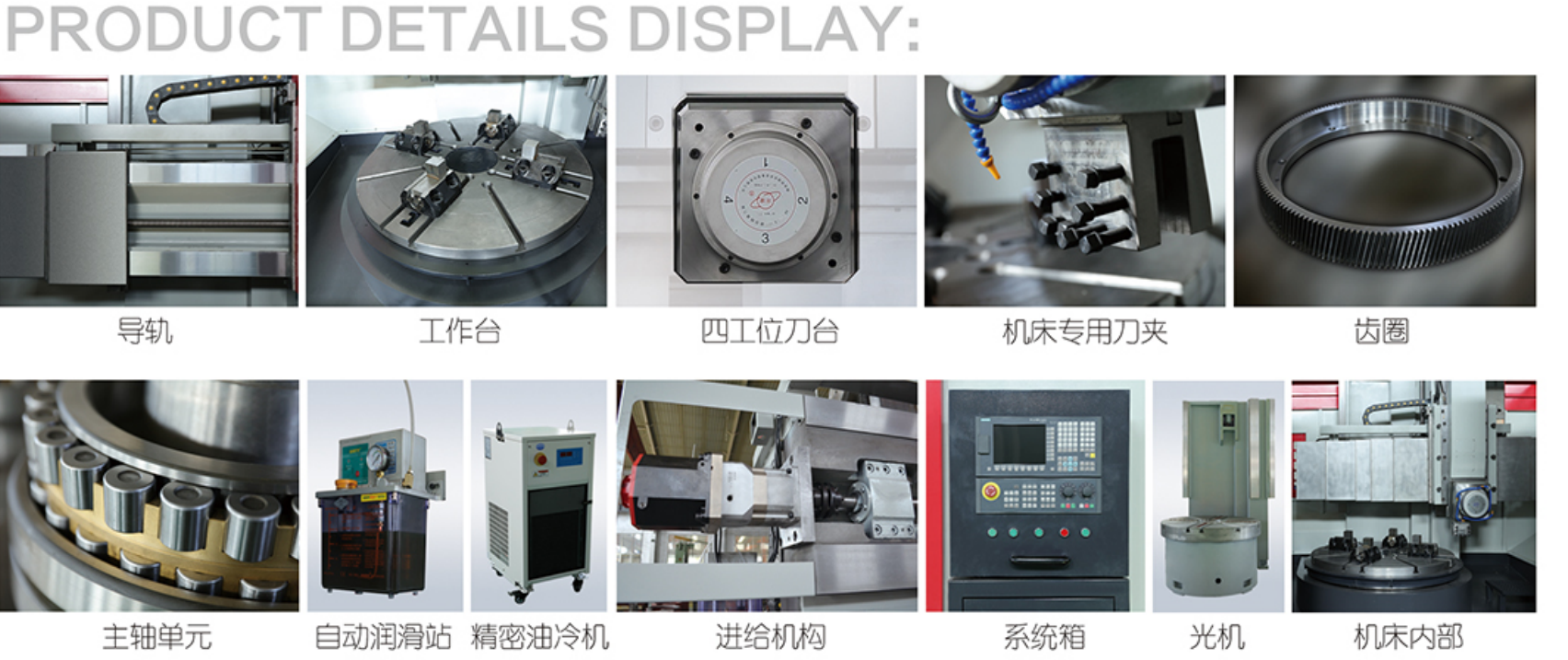

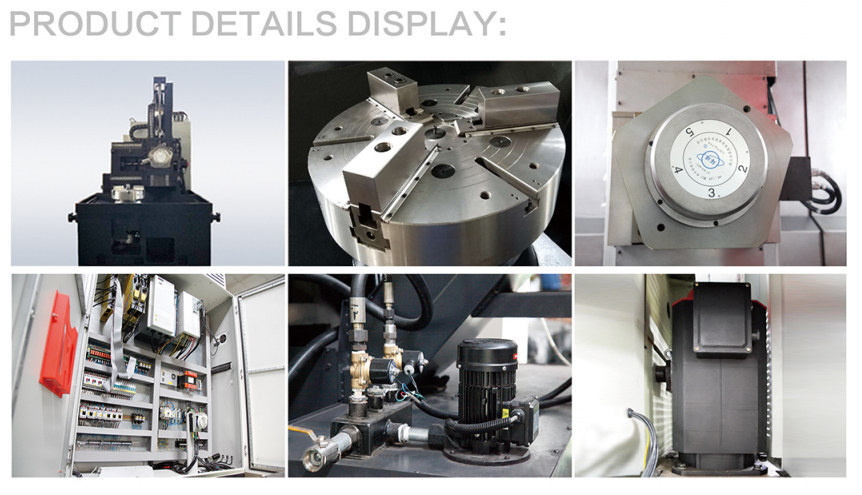

2.This machine tool is mainly composed of column, workbench, beam, vertical tool rest, main transmission gearbox, beam lifting mechanism, vertical tool rest feed mechanism, beam guide rail protection device, complete machine fully enclosed protective cover, electrical system, hydraulic system, cooling device, etc.

CK52E CNC Vertical lathe series(Four models available,email to get more details)

Product structure features:

1.This series of machine tools is applicable to the motor, water hammer, aviation, mining machinery, metallurgy and machinery industries. It can process ferrous metal, nonferrous metal and some non-metallic material workpieces. On the machine tool, it can finish rough and finish machining of internal and external cylindrical surfaces, conical surfaces, end faces, metric and inch threads, grooves, etc.

2.The large parts of the foundation are of integral casting structure, made of high-strength low-stress cast iron. After casting, they are subject to fine fire, rough machining and aging treatment. The column guide rail is subject to grinding treatment. The beam guide rail and ram guide rail are subject to medium frequency quenching and grinding treatment.

3.The main drive of this series of machine tools is DC motor+DC speed regulation or AC variable frequency motor+frequency converter. The worktable is divided into wave guide rail and hydrostatic guide rail for user selection. (See the technical parameter table for details) The main shaft bearing of the hydrostatic guide worktable adopts high-precision double-row short cylindrical roller bearing, and the hydrostatic oil adopts constant temperature cooling, thus ensuring that the machine tool has enough high rotation accuracy and sufficient rigidity, strength and thermal stability, and has constant linear speed cutting function.

4.The feeding system for horizontal and vertical movement of vertical tool rest is driven by AC servo motor and dynamic ball screw, with high transmission efficiency and long service life. The left and right tool holders are hydraulically balanced.

5.The machine tool is equipped with advanced functional parts at home and abroad. The machine tool is beautiful in appearance, pleasant and reliable in function.

6.According to special requirements, it can provide complete machine protective cover, chip remover, electric spindle grinding head, cooling device, lathe integrated vertical tool holder, four-station electric tool table, etc.

7.This series of machine tools can be configured with single and double vertical tool holders according to user requirements. The configuration of double tool holders can be divided into three forms: (left NC tool holder, stone common tool holder), double common tool holders, and double NC tool holders.

8.FANUC, SIEMENS or Beijing KND system are selected for the numerical control system, and other numerical control systems can be selected by the user.

SCVL CNC Single column Vertical lathe series(three models available,email to get more details)

Product structure features:

1.Taiwan hydraulic chuck is adopted, which has high positioning accuracy and good stability. At the same time, the labor intensity of operators is reduced, the clamping time of workers is reduced, and the labor production efficiency is improved.

2.Taiwan's high-performance spindle is adopted, and the spindle handle and face are subject to Taiwan's scraping technology. The form of face contact is adopted, which is different from the point contact and first contact of other manufacturers.

3.Taiwan 8-station tool rest or vertical electric tool table.

4.Taiwan ball screw and Taiwan electrical components.

5.The unique closed protective cover of the whole machine can effectively prevent the cutting elbow and the coolant from splashing around, thus achieving the goal of environmental protection.

SVL CNC Single column high speed Vertical lathe series(three models available,email to get more details)

Product structure features:

1.SVL CNC single-column vertical turning machining center is equipped with Fanuc 01 TF system, two-axis (X, Z) linkage, 12-position disc tool magazine, and ram tool taking mode. It is applicable to cemented carbide and ceramic tools, and can rough and finish the internal and external cylindrical surfaces, internal and external conical surfaces, planes, threads and arc surfaces of parts made of ferrous metals, non-ferrous metals and some non-metallic materials at high speed.

2.The main drive is driven by double-base speed spindle servo motor and controlled by servo. The dual-speed spindle servo drive system has closed loop speed regulation within the full speed range, with 1.5 times overload capacity, and can output effective torque at zero speed. The main shaft bearing adopts the tapered cross roller bearing structure, which has the characteristics of high precision, high rigidity, high load, high speed, low friction, etc. Therefore, the machine tool itself has high rotation accuracy and rigidity.

3.The X-axis and Z-axis servo motors are directly connected with the ball screw through the flexible coupling, and the guide rail is in the form of sliding guide rail (hard rail). The position of the linear coordinate is detected by the entrance grating ruler, so as to realize the full closed-loop control of the two-axis linkage.

4.The complete machine is equipped with a fully enclosed protective cover, which has the protection and collection functions of iron chips and coolant. The protective cover has enough space for chip cleaning.

CA51E Single column Vertical lathe series(Four models available,email to get more details)

Product structure features:

1.This series of machine tools is suitable for machining in various industries, and can be used for rough and fine turning of internal and external cylindrical surfaces, conical surfaces, end faces, grooving, cutting, etc., and can also be used for lithium inner hole process

2.The foundation parts are of integral casting structure and made of high-strength low-stress cast iron. After casting, they are subject to tempering, rough machining and aging treatment. The column guide rail is subject to grinding treatment. The beam guide rail and ram guide rail are subject to medium frequency quenching and grinding treatment.

3.The main drive adopts 16-step speed change, and the workbench speed change is controlled by solenoid valve; All transmission gears adopt high-frequency quenching grinding process.

4.The worktable adopts the form of rolling guide rail, so the worktable has large bearing capacity and high rotation accuracy.

5.The vertical tool rest is equipped with a five-angle tool table, which is positioned with high-precision mouse tooth plate; The tool rest is hydraulically balanced; The horizontal and vertical movement of the vertical tool rest is driven by a sliding lead screw, and the tool rest is driven by a three-phase AC motor; The guide rail is in the form of sliding guide rail, and its matched guide rail surface is pasted with high-strength polytetrafluoroethylene soft belt.

6.The hydraulic system is equipped with a flow transmitter to ensure the stable flow of lubricating oil on the workbench.

7.The machine tool is controlled by PLC, so it has high reliability. The electrical wiring is strictly executed according to the process.

8.The machine tool is beautiful in appearance, pleasant and convenient in operation and maintenance

9.Digital display device, T-shaped ram, square ram, etc. can be provided according to special requirements.

C52E double column Vertical lathe series(Four models available,email to get more details)

Product structure features:

1.This series of machine tools are applicable to the motor, water hammer, aviation, mining machinery, metallurgy and general machinery industries, and are used for rough and finishing machining of internal and external cylindrical surfaces, conical surfaces, end faces, grooves, etc.

2.The foundation parts are of integral casting structure and made of high-strength low-stress cast iron. After casting, they are subject to fire treatment and aging treatment after rough machining. The column guide rail is subject to grinding treatment. The beam guide rail and ram guide rail are subject to medium frequency quenching and grinding treatment.

3.The main drive of this series of machine tools is driven by an AC motor, and the main drive speed is controlled by a solenoid valve with a 16-step speed change. All gear wheels in the gearbox adopt high-frequency quenching grinding process. The worktable is divided into three types: sliding, static and fluctuating guide rails.

4.The horizontal and vertical feed of the vertical tool rest is driven by the wave ball lead screw, which is moved by the servo AC motor in three zones, thus realizing automation. The left and right tool holders are hydraulically balanced; The horizontal and vertical feeding adopts sliding guide rail, and its matched guide rail is pasted with high-strength polytetrafluoroethylene soft belt.

5.The hydraulic system is equipped with a flow transmitter to ensure the stable flow of lubricating oil on the workbench.

6.The machine tool is controlled by PLC, so it has high reliability. The electrical wiring is strictly executed according to the process.

7.The machine tool is beautiful in appearance, pleasant and convenient in operation and maintenance.

8.According to special requirements, power spindle grinding head, cooling device, digital display and other accessories can be provided.

9.The horizontal and vertical drag lines and button station housings of this series of machine tools are respectively domestic famous and high-quality products.

10.CNC system can be configured according to user requirements.

Contact me at once:

susan@tongyuanlathe.com

Mobile/whatsapp/wechat:+8615165964868